Injection molding is one of the most widely used manufacturing processes for creating plastic components with high efficiency and precision. However, not all plastics behave the same way during molding. Two primary categories—thermoplastics and thermosets—offer distinct advantages, limitations, and application areas.

At DXTSEALS, we provide both thermoplastic and thermoset injection molding services, helping clients choose the best material and process to meet their functional and performance requirements.

What Are Thermoplastics and Thermosets?

🔹 Thermoplastics

Thermoplastics are polymers that become soft and moldable when heated and return to a solid state when cooled. They can be re-melted and reshaped multiple times without significant degradation.

Common Thermoplastics:

-

ABS (Acrylonitrile Butadiene Styrene)

-

PP (Polypropylene)

-

PC (Polycarbonate)

-

Nylon (PA)

-

PET (Polyethylene Terephthalate)

🔹 Thermosets

Thermosetting plastics undergo a chemical curing process during molding that makes the material harden permanently. Once cured, thermosets cannot be re-melted or reformed.

Common Thermosets:

-

Epoxy

-

Phenolic

-

Melamine formaldehyde

-

Urea formaldehyde

-

Silicone (when used in thermosetting applications)

Key Differences Between Thermoplastic and Thermoset Molding

| Aspect | Thermoplastics | Thermosets |

|---|---|---|

| Recyclability | Re-meltable and recyclable | Not recyclable after curing |

| Processing Temperature | Typically lower | Requires higher curing temperatures |

| Cycle Time | Shorter, faster production | Longer due to curing time |

| Mechanical Properties | Good flexibility, less rigid | Higher rigidity, better dimensional stability |

| Heat Resistance | Lower heat resistance | Excellent thermal stability |

| Tooling Requirements | Moderate | Often requires more robust molds and pressure |

| Cost | Generally lower | May be higher due to complex processing |

Applications of Thermoplastic Injection Molding

Thermoplastics are ideal for:

✅ Consumer products (toys, appliances, housings)

✅ Automotive components (interior panels, clips)

✅ Medical devices (syringes, enclosures)

✅ Electronics (connectors, switch casings)

✅ Packaging and containers

Applications of Thermoset Injection Molding

Thermosets are used in applications requiring high strength, thermal stability, and chemical resistance, such as:

✅ Electrical insulators and circuit components

✅ Automotive parts (brake pads, engine gaskets)

✅ High-heat environments (cookware handles, oven parts)

✅ Aerospace and defense components

✅ Industrial-grade seals and valves

Choosing the Right Molding Process

When deciding between thermoplastic and thermoset injection molding, consider:

-

Functional requirements (rigidity, temperature tolerance)

-

Part geometry and complexity

-

Production volume and cost targets

-

Recyclability and environmental goals

Why DXTSEALS?

At DXTSEALS, we offer:

🔧 Expert Material Consultation – Helping you choose the ideal plastic for your application

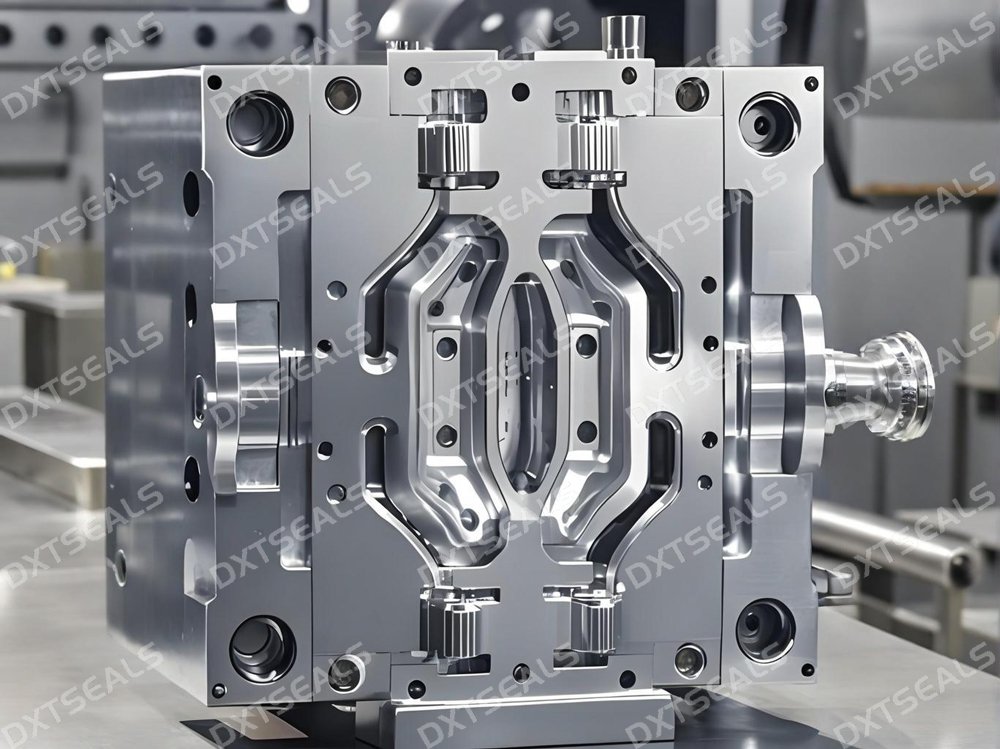

🏭 State-of-the-Art Injection Molding Facilities – Equipped for both thermoplastic and thermoset processes

📐 Custom Mold Design & Fabrication – Tailored to your project needs

✔️ Strict Quality Control – Ensuring precision and consistency

📦 End-to-End Service – From prototyping to mass production and delivery

Conclusion

Understanding the differences between thermoplastic and thermoset injection molding is essential to choosing the right method for your product. Whether you need flexible, recyclable thermoplastics or durable, heat-resistant thermosets, DXTSEALS provides customized solutions for every industry.