Introduction

High-precision custom springs play a vital role in the functionality of musical instruments, from pianos to stringed instruments and percussion devices. These springs are designed to meet the exacting requirements of musical mechanisms, ensuring smooth operation, precision, and durability. Whether used in a piano's action mechanism, a guitar’s tuning system, or a drum pedal, high-precision custom springs contribute significantly to the overall performance and longevity of musical instruments.

In this article, we will explore the key features and durability of these custom-made springs and explain why they are indispensable in the world of musical instrument design.

1. Key Features of High-Precision Custom Springs for Musical Instruments

High-precision custom springs must meet a set of stringent requirements to perform effectively in musical instruments. These requirements include optimal tension, flexibility, and durability. Here are the key features that make high-precision springs essential for musical instrument design:

a. Accurate Tension and Compression

One of the most critical characteristics of custom springs in musical instruments is their ability to provide precise tension and compression. Springs in musical instruments, such as piano action springs or guitar string tensioners, need to offer consistent and reliable force. Any fluctuation in tension can affect the instrument’s tuning, responsiveness, and overall performance.

- Benefit: Custom springs provide the exact force needed to maintain tuning stability, key response, or pedal function.

b. Tailored to Specific Instruments

Each musical instrument has unique design specifications and mechanical requirements. High-precision custom springs are engineered to meet these specific needs. Whether it's a piano's action mechanism, a guitar’s bridge system, or a drum pedal, custom springs can be made to fit the exact dimensions and performance expectations of the instrument.

- Benefit: Custom-made springs ensure compatibility with the instrument’s design, providing optimal performance and long-lasting reliability.

c. Consistent Performance Under Stress

High-precision custom springs must endure repetitive stress over time, especially in applications such as piano action systems, where springs are constantly in motion. These springs are designed to operate smoothly and consistently, even under intense pressure or movement.

- Benefit: Custom springs offer reliable performance under long-term use, reducing the need for frequent repairs or replacements.

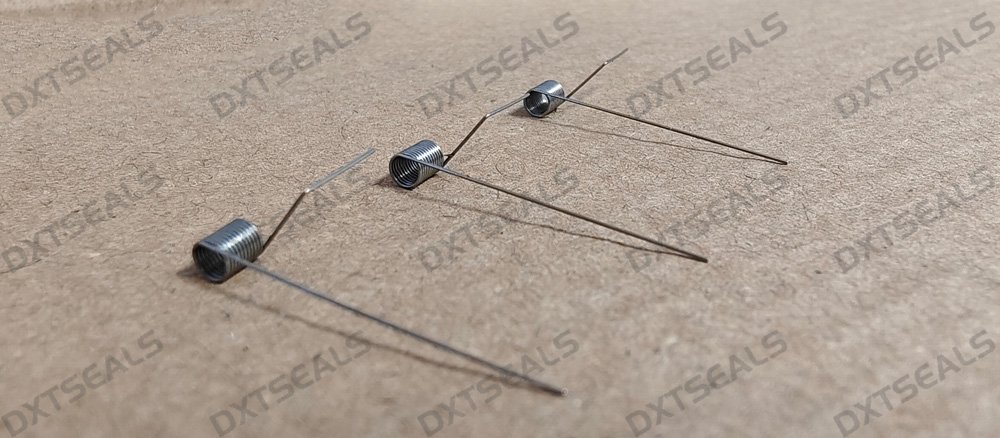

d. High-Quality Materials for Durability

The durability of high-precision custom springs depends largely on the material used. For musical instruments, manufacturers often choose materials like stainless steel, carbon steel, or special alloys to provide optimal performance and resistance to wear and fatigue. Stainless steel, in particular, is known for its resistance to corrosion and rust, which is especially important for instruments exposed to varying environmental conditions.

- Benefit: Springs made from high-quality materials maintain their performance over time, even in harsh conditions.

2. Durability of High-Precision Custom Springs

Durability is a key factor when it comes to the longevity of any musical instrument, and custom springs are no exception. These springs must endure years of use while maintaining their function and form. The durability of high-precision springs in musical instruments is influenced by several factors:

a. Resistance to Fatigue

Musical instrument springs, especially in instruments like pianos or drum pedals, undergo continuous cycling (compression and expansion) over extended periods. High-precision custom springs are designed to withstand this repetitive stress without losing their strength, elasticity, or shape.

- Benefit: Long lifespan without compromising on performance or causing the instrument to lose its mechanical integrity.

b. Corrosion Resistance

Environmental factors, such as humidity, moisture, and air exposure, can significantly affect the performance of springs made from inferior materials. High-precision custom springs, often made from materials like stainless steel, titanium, or carbon steel, are resistant to rust and corrosion, ensuring that the springs maintain their performance even in humid or corrosive environments.

- Benefit: Springs that last longer and perform reliably, even in environments with fluctuating humidity and temperature.

c. Shock Resistance

In instruments like percussion instruments or stringed instruments, the springs must endure sudden shocks, impacts, or vibrations. High-precision custom springs are designed to absorb these impacts without losing their elasticity or breaking under pressure. This resistance to sudden stress ensures the longevity of both the spring and the instrument.

- Benefit: Custom springs protect the internal mechanisms of the instrument from damage caused by vibrations or shocks.

d. Precision Manufacturing for Consistent Performance

The high-precision manufacturing process ensures that each spring is made to exact specifications, which is crucial for maintaining the performance of musical instruments over time. The precise tension and durability of these springs allow musicians to experience consistent, reliable performance, whether for tuning adjustments, key movements, or pedal actions.

- Benefit: Instruments maintain stable tuning, precise key responses, and smooth pedal functions throughout their use.

3. Applications of High-Precision Custom Springs in Musical Instruments

High-precision custom springs are used in a wide range of musical instruments, with each application benefiting from the springs’ tailored features and durability:

- Pianos: In pianos, high-precision springs are used in the action system, where they help control key movements, hammer actions, and pedal functions. The springs ensure that the keys return smoothly and the pedals perform consistently.

- Guitars: Springs are used in the bridge system, tremolo mechanisms, and tuning machines. Custom springs allow for precise tuning adjustments and stable string tension.

- Drums: Drum pedals rely on high-precision springs to regulate the tension and movement of the foot pedal. The durability of these springs ensures that the pedal mechanism works smoothly over time.

- Orchestral Instruments: Some orchestral instruments, such as harps and organ pipes, also rely on custom springs for key and pedal action systems, helping musicians achieve the desired sound and performance.

4. Conclusion

High-precision custom springs are indispensable in the design and performance of musical instruments. Their ability to provide precise tension, resistance to fatigue, corrosion, and shock, and their overall durability make them crucial components in ensuring smooth, reliable operation. By choosing the right materials and manufacturing processes, these springs significantly enhance the longevity and performance of musical instruments, allowing musicians to enjoy optimal performance for years.