Metal O-Rings

DXTSEALS offers a comprehensive range of high-quality metal O-rings to ensure secure and reliable sealing for vacuum, gases, and liquids. Our metal O-rings are engineered to perform exceptionally well, even under extreme conditions. These static and metallic sealing elements can withstand ultrahigh vacuum environments and pressures of up to 5500 bar.

Designed for durability and versatility, DXTSEALS metal O-rings are suitable for a wide temperature range, spanning from -269 degrees Celsius to +750 degrees Celsius. If you need higher temperature applications, please contact our team. Furthermore, our rings exhibit excellent resistance to radioactive radiation, chlorides, corrosion, and other aggressive substances. Our metal O-rings retain superior performance over time and show no signs of aging during usage and storage.

Advantages & Usage

seals vacuum, gases and liquids

pressure ranges from UHV up to 5500bar

service temperatures from -269°C to 750°C.

lowest leakage rates through additional coating

Resistant to explosive decompression

Simple force calculations (force shunt)

Metal O-Ring Types

Three types of metal O-rings are available: the Standard Type, the Self-energizing Type, and the Pressure-filled Type. Each type possesses distinct characteristics and is suited for specific applications, offering various sealing solutions to meet diverse requirements.

The Standard Type of metal O-rings, made from various metallic tubings or solid wire, is an economical choice for applications with low to moderate pressure or vacuum ratios. It is not self-energizing or pressure-filled.

The Self-energizing Type of metal O-rings feature borings and grooves on the inside or outside diameter, allowing the O-ring to experience the same pressure as the system. This design leverages the system pressure to enhance the sealing performance.

The Pressure-filled Type of metal O-rings is specifically designed for high-temperature applications ranging from 425 degrees Celsius to 980 degrees Celsius. These O-rings contain a gas filling of approximately 40 bar pressure or higher. The gas pressure increases with rising temperatures, compensating for the initial tension deficiency of the flanged joint and increasing the sealing force. While they offer lower pressure resistance compared to the self-energizing type, they excel in high-temperature environments.

Pressure

O-Ring Type

vacuum up to 6.8 bar

standard type

6.8bar and above

self-energizing

vacuum to approx.20 bar

pressure-filled

O-Ring Material

Selecting the appropriate metal for O-rings is a critical decision that hinges on understanding the unique properties, strengths, and limitations of various metal options available

SS321 (Stainless Steel 321)

This is a specific type of stainless steel that is stabilized with titanium. The titanium helps prevent chromium carbide precipitation, which can occur when the steel is exposed to temperatures above 371°C. This makes SS321 more resistant to intergranular corrosion than other types of stainless steel.

Maximum Service Temperature: 371°C

Inconel 600

Inconel 600 is a nickel-chromium alloy favored for its good oxidation resistance at moderate service temperatures. It also exhibits good resistance to carburizing and chloride-containing environments. The alloy is often used in corrosion-resisting applications due to its high nickel content, which provides resistance to reducing environments, and its chromium content, which provides resistance to weaker oxidizing environments.

Maximum Service Temperature: 538 °C

Inconel X-750

Inconel X-750 is an age-hardened, nickel-based superalloy known for its high-temperature strength and corrosion resistance. It’s particularly useful in high-temperature conditions, offering high tensile and creep rupture properties. The alloy’s strength can be optimized at temperatures between 700 and 975 degrees Celsius.

Generally, stainless steel, like SS321, tends to be less expensive than nickel-based alloys like Inconel. If cost is a significant factor, SS321 might be the more economical choice.

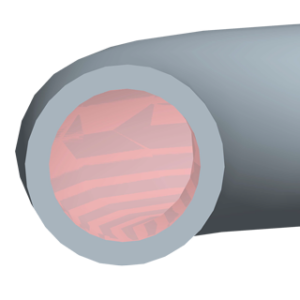

Coating

Coating or electroplating the metal O-ring enhances adhesion and creates a more ductile (softer) surface, allowing it to adapt to microscopic imperfections in the groove or flange.

When the O-ring is compressed, the coating fills the microscopic irregularities of the opposing seal, ensuring excellent sealing. The achieved tightness, measured as the leakage rate, depends on the interaction between the ring and the surface quality of the sealing.

The need for a coating and its thickness is determined by the desired leakage rate and the surface quality of the groove and flange. The coating must match the ring's pressing load to ensure effective sealing.

Coating Materials

Copper:

A soft material that improves sealing performance and reduces leakage rates. It provides good corrosion resistance and enhances tribo-oxidation resistance. It's often used for steel rings when lubrication is essential.

Silver:

Offers better oxidation and chemical resistance. It's cost-effective, provides good adhesion, and is suitable for high-temperature applications. Silver increases operational safety and is less expensive than gold coating.

PTFE:

This polymer layer provides excellent sliding properties, low friction coefficient, and high elasticity. It offers excellent corrosion resistance and is suitable for use in aggressive environments. Despite being more expensive, it's considered cost-effective due to metal seals' performance and service life.

Gold:

Gold offers excellent corrosion resistance, wear resistance, and workability. It's suitable for high-temperature applications and dynamic operations due to its malleability. However, it's the most expensive coating technique.

Nickel:

Nickel coating offers high hardness, wear resistance, and good corrosion resistance. It's suitable for high-temperature and pressure applications and reduces the static friction of metal seals. It is a substantial barrier for the base metal surface from corrosion attacks.

Heat Treatment

Rings can undergo various heat treatments based on their materials and uses. Appropriate heat treatment can enhance both the performance and lifespan of the rings:

Mechanical Properties:

Heat treatment boosts the mechanical properties of the metal, such as hardness, toughness, and tensile strength. This can enhance the durability and wear resistance of the O-rings, which is crucial in high-pressure or high-temperature applications.

Internal Stresses:

The manufacturing process can induce internal stresses in the metal. If not alleviated, these stresses could lead to deformation or failure of the O-ring during use. Heat treatment can help to relieve these stresses and stabilize the metal.

Corrosion Resistance:

Certain heat treatment processes can enhance the corrosion resistance of the metal. This can be advantageous in applications where the O-ring is exposed to corrosive substances.

Dimensional Stability:

Heat treatment can help ensure the O-ring maintains its shape and size under varying temperature conditions.

Following heat treatments are possible:

| Heat treatment | Description |

|---|---|

| HT1 | work hardened |

| HT2 | age hardened |

| HT3 | Solution annealing + precipitation hardened SC |

| HT4 | Solution annealing + precipitation hardened Std |

| HT5 | Heat treatment NACE MR 0175 |

Not all heat treatments are applicable for every material, the following table listst the applicable treatments:

| Material | Material Code | Heat Treatments |

|---|---|---|

| SS321 | 1.4541 | HT1 |

| Inconel 600 | 2.4816 | HT1 |

| Inconel X-750 | 2.4669 | HT1, HT2, HT3, HT4 |

| Inconel 718 | 2.4668 | HT1, HT2, HT3, HT4, HT5 |

dxtseals-metalorings.The customer or DXTSEALS can decide the specification for this treatment, provided all necessary parameters and requirements are available.

Ring Diameter and Tube Wall Thickness

The tube profile section is determined by the ring's outside diameter, the required pressure force, and the available space.

The wall thickness must be chosen so that the appropriate deformation yields the necessary pressure force. The following information includes the standard wall thicknesses that can be used for any diameter.

| tube outside diameter [mm] | ring outside diameter [mm] | standard tube wall thicknesses [mm] | |

|---|---|---|---|

| min. | max. | ||

| 0.9 | 6.4 | 101 | 0.15 |

| 1.6 | 15.9 | 254 | 0.25 / 0.30 / 0.36 |

| 2.4 | 25.4 | 508 | 0.25 / 0.46 |

| 3.2 | 50.8 | 1016 | 0.25 / 0.51 / 0.64 |

| 4.0 | 76.2 | 1270 | 0.51 / 0.64 |

| 4.8 | 101.0 | 1524 | 0.51 / 0.81 |

| 6.4 | 127.0 | 2500 | 0.64 / 0.81 |

Bear in mind that:

For seals with electroplated surfaces and a tube wall thickness of 3.2 mm diameter, a load of approximately 72 N/mm around the length results in plastic deformation of the electroplating.

For tubes with a diameter of 3.2 mm, a pressure of 140 N/mm around the length is needed. Teflon-coated rings undergo plastic deformation under a load of 18 N/mm around the length.

Groove dimensions

The appropriate size and finish quality of the groove are as crucial as the O-ring itself for the seal's application.

The suggested groove dimensions for internal and external pressure applications below should be considered general guidelines for preparing sealing surfaces.

| tube outside dia. [mm] | groove depth [mm] min. max. | groove width [mm] min. | ring tolerance [mm] | spring-back [mm] | groove outside dia.[mm] (for interanl pressure) | groove inside dia.[mm] (for exteranl pressure) |

|---|---|---|---|---|---|---|

| 0.9 | 0.60-0.68 | 1.4 | 0.08 | ~0.05 | B+0.10 / 0.20 | A-0.10 / 0.20 |

| 1.6 | 1.15-1.25 | 2.3 | 0.08 | ~0.07 | B+0.10 / 0.20 | A-0.10 / 0.20 |

| 2.4 | 1.80-1.95 | 3.0 | 0.13 | ~0.07 | B+0.15 / 0.25 | A-0.15 / 0.25 |

| 3.2 | 2.40-2.60 | 4.0 | 0.13 | ~0.08 | B+0.20 / 0.35 | A-0.20 / 0.35 |

| 4.0 | 3.05-3.25 | 5.0 | 0.15 | ~0.10 | B+0.25 / 0.40 | A-0.25 / 0.40 |

| 4.8 | 3.70-3.90 | 6.2 | 0.18 | ~0.10 | B+0.25 / 0.40 | A-0.25 / 0.40 |

| 6.4 | 5.00-5.20 | 8.2 | 0.20 | ~0.13 | B+0.30 / 0.50 | A-0.30 / 0.50 |

The dimensions listed apply to rings that are not electroplated. For rings with a profile section of 0.9 mm, the groove depths are increased by twice the coating thickness. However, there is no increase in groove depth for electroplated or coated rings with a tube diameter of 1.6 mm or more.

Quality of Finish

Recommended qualities of finish of the groove and the jointing face of the flange:

0.1 - 0.4 µm Ra - for uncoated rings

0.4 to 0.8 µm Ra - for electroplated or coated rings

Ghost lines on the groove surface or flange facing must be free of dirt, grinding dust, or other impurities. The following surface roughnesses are usual in practical operation:

| Surface roughness (µm) | |

|---|---|

| Coating O-Ring | Uncoated O-ring |

| Ra = 0.4 - 0.4 to 0.8 µm | Ra = 0.1 - 0.4 µm Ra |

Message to us (click here to show/hidden)