Introduction

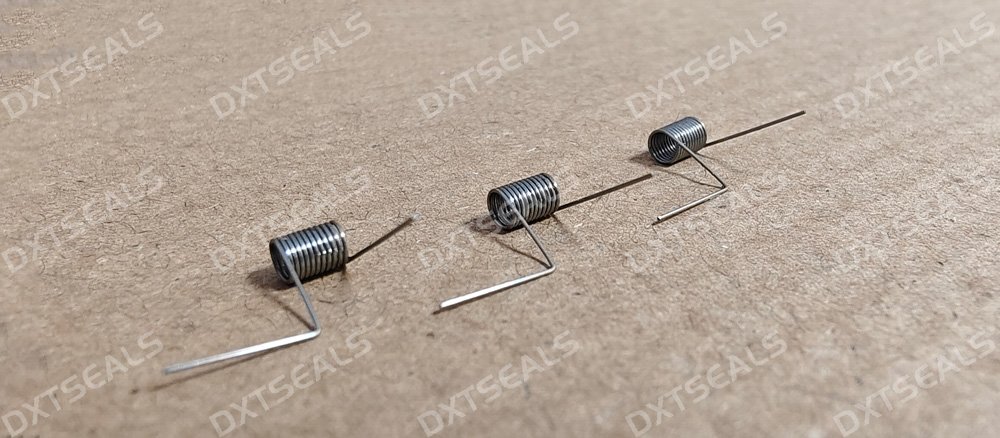

In the world of musical instruments, precision and durability are essential, especially when it comes to the springs used in the mechanisms. Springs play a critical role in ensuring smooth operations, whether it's the action system in a piano or the bridge system in a guitar. One popular material used for manufacturing springs for musical instruments is 304 stainless steel. Known for its durability, resistance to corrosion, and flexibility, 304 stainless steel is frequently chosen for high-performance springs.

But how durable are 304 stainless steel springs in musical instruments, and why is this material so well-suited for use in instruments like pianos, guitars, and other precision devices? In this article, we'll dive into the characteristics of 304 stainless steel and explore why it's an excellent choice for custom springs used in musical instruments.

1. Understanding 304 Stainless Steel

Before delving into the performance of 304 stainless steel springs in musical instruments, let's first understand why 304 stainless steel is widely used for custom spring manufacturing.

304 stainless steel is austenitic steel, which is known for its excellent corrosion resistance, strength, and formability. It's a non-magnetic, highly durable material that can withstand harsh environmental conditions, making it an ideal choice for a wide range of industrial applications, including musical instruments.

Key properties of 304 stainless steel:

- Corrosion Resistance: It resists corrosion from many acids and harsh environments, which is crucial for springs used in musical instruments exposed to varying humidity and temperatures.

- Strength and Durability: Stainless steel offers good tensile strength and flexibility, allowing springs to endure continuous use without deforming or breaking.

- Non-reactive: 304 stainless steel does not react with food, moisture, or cleaning products, making it suitable for use in sensitive musical mechanisms.

2. Durability of 304 Stainless Steel Springs in Musical Instruments

Musical instruments, especially precision devices like pianos, guitars, and drum pedals, require springs that can perform reliably over time without losing their shape or function. 304 stainless steel springs are known for their exceptional durability and longevity under frequent mechanical stress, making them an ideal choice for musical applications. Here's why:

a. Resistance to Wear and Fatigue

Springs in musical instruments are often subject to repetitive motion, such as the action mechanism in pianos or the movement of pedals in a drum set. Over time, many materials can lose their shape or break due to metal fatigue. However, 304 stainless steel is highly resistant to this form of wear. It maintains its elasticity and strength under constant use, ensuring that the springs will last for a long time without needing frequent replacement.

- Benefit: 304 stainless steel springs offer long-lasting performance, even in high-use environments like pianos or percussion systems.

b. Corrosion Resistance for Longevity

Musical instruments are exposed to varying levels of humidity, temperature fluctuations, and even perspiration or moisture from musicians' hands. These conditions can cause certain materials to corrode or degrade. 304 stainless steel, however, is highly resistant to rust and corrosion. This resistance ensures that springs will continue to perform optimally even in environments prone to moisture or changing conditions.

- Benefit: 304 stainless steel springs maintain their integrity and performance over time, ensuring the instrument remains in top working condition.

c. Maintaining Precision Under Stress

In precision-driven musical instruments, such as pianos and guitars, springs must maintain consistent force and tension over extended periods of time. The high-quality material of 304 stainless steel allows springs to retain their shape and strength under stress without losing their precision, even after years of continuous use.

- Benefit: 304 stainless steel springs provide accurate, consistent performance, whether in tuning systems, key movements, or pedal actions.

d. Minimal Maintenance Needs

Another key advantage of 304 stainless steel in musical instrument springs is its low maintenance requirements. Due to its corrosion resistance and durability, 304 stainless steel springs are less likely to require frequent repairs or replacements, which is crucial for both manufacturers and musicians who need dependable instruments.

- Benefit: Reduced maintenance and replacement costs for instruments with 304 stainless steel springs.

3. Applications of 304 Stainless Steel Springs in Musical Instruments

304 stainless steel springs are used in a variety of musical instruments to enhance their functionality and performance. Here are some examples:

a. Pianos

Piano action systems rely on multiple springs to control the key movements, hammers, and pedals. 304 stainless steel springs are commonly used in pianos for their ability to provide the required tension while resisting wear and corrosion.

- Use Case: Springs in piano action systems and pedal mechanisms.

b. Guitars

Guitars, particularly electric guitars, use springs for their tremolo systems, bridge assemblies, and tuning machines. 304 stainless steel springs ensure that the guitar maintains stable tuning and allows smooth adjustments to the string tension.

- Use Case: Springs for tremolo systems, bridge mechanisms, and tuners.

c. Drums

In percussion instruments like drums, the springs in foot pedals need to be strong, durable, and resistant to corrosion. 304 stainless steel springs are ideal for drum pedal mechanisms because they can handle repeated stress without deforming.

- Use Case: Springs in drum pedal systems for tension and movement.

d. Other Musical Instruments

Other musical instruments, such as organs, harps, and accordions, also rely on custom springs for their pedal and key action systems. 304 stainless steel provides the strength and reliability needed for these complex instruments.

- Use Case: Springs in key and pedal mechanisms of various orchestral and mechanical instruments.

4. Conclusion

304 stainless steel is an excellent material choice for manufacturing high-precision springs used in musical instruments. Its durability, corrosion resistance, and strength make it ideal for withstanding the repetitive motions and environmental conditions typical in musical instruments. Whether used in pianos, guitars, or percussion systems, 304 stainless steel springs ensure long-lasting performance and reliable functionality. Musicians and manufacturers alike can count on these springs to maintain the precision and performance of their instruments for years to come.